The article by Brooks, referenced in View from the Q, uses terms like conversion and epiphany to describe the recognition and adoption of quality. Deming is compared to the famous evangelist, Billy Graham.

My own conversion was at the feet of the Billy Graham of quality, Dr. W Edwards Deming. I had the great good fortune to attend six of his four-day seminars during the final years of his life, and even had some brief conversations with him. My conversion was literally an epiphany.

In this context, an epiphany can also refer to secular discoveries (i.e. Pythagoras and the 47th problem of Euclid (sum of squares in sides of right-angled triangle = square of hypotenuse a.k.a 3-4-5 unit right-angled triangle) or Archimedes (water displacement in the bathtub to measure volume, to which he cried “Eureka!”).

A Quality Epiphany or “Eureka Moment” can be generated consistently in three ways:

- Demonstrating cost reductions by controlling losses and penalties by meeting and complying with requirements, regulations, and customer specifications.

- Projecting revenue expansions by increasing business opportunities and entry to new markets demanding higher levels of quality assurance and performance.

- Realizing improved operational efficiency and predictability by optimizing methods and practices to reduce waste, improve predictability, and increase capacity with existing resources.

How do we explain this in a simple and memorable manner? I have an example below:

In response to the latest View from the Q posting, I wanted to provide a very simple and timeless explanation of Quality, from which more detailed explanations can be made to fully understand our profession.

To summarize:

To summarize:

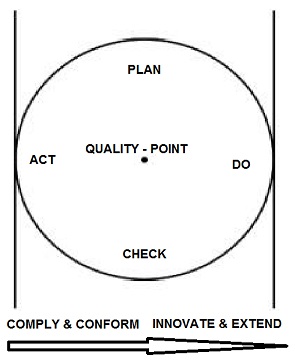

- The PDCA (Plan, Do, Check, Act) cycle is the core of all activities related to Quality, with the Quality function at the center point of all activities.

- The scope of the PDCA cycle (represented by the area within the circle) reflects the domain of the Quality function, and its influence within its parent organization

- The repetitive and continuous PDCA cycle (originating from Shewhart and popularized by Deming) reinforces the constant and perpetual progression from uncontrolled chaos to predictable ideals.

- The two parallel lines bordering the circle have different meanings. The left line represents the minimum levels of compliance, conformity, and “good enough” quality. The right line represents the desired state of having quality-driven breakthroughs, innovations, and extensions to the solution.

- The role and value of the Quality function can be shown visually in this context, as a way to continually perform PDCA-related actions to not only guarantee compliance and conformity, but to advance the organization toward competitive advantages.

- Imagine that the PDCA cycle is not only in continual motion, but is progressing along a maturity track from the boundary of minimal compliance toward the infinite possibilities of unlimited innovation and extensions. Consider the progression of Honda over the last 50 years from scooters and outboard motors to vehicles and aircraft.

The best way to take this from theory to practice is to demonstrate quality in all of its forms (Lean, Inspection, Process Controls, Management Systems, Risk Management, Business Process Improvement etc.) and show where value and gains are added for the organization and the people involved.